Choosing the right industrial touchscreen monitor: key factors to consider

For many industries that rely on monitors for their work, finding the right industrial touchscreen monitor is crucial. These monitors are designed to withstand harsh environments and provide the skills needed to operate efficiently. When choosing an industrial touch screen monitor, it is important to consider factors such as touchscreen technology, ruggedness and durability, customisation options, connectivity and different types of monitors to ensure successful performance in different environments. As different industrial touchscreen monitor suppliers offer customised solutions, it is important for businesses to assess their specific requirements before purchasing any new monitors or upgrades. This is especially important in industrial environments that require specialised skills to work efficiently. Whether your industrial environment requires industrial touchscreen monitors or you want to get in touch with a touchscreen technology specialist, it's vital to make informed decisions and utilise your skills.

Durability

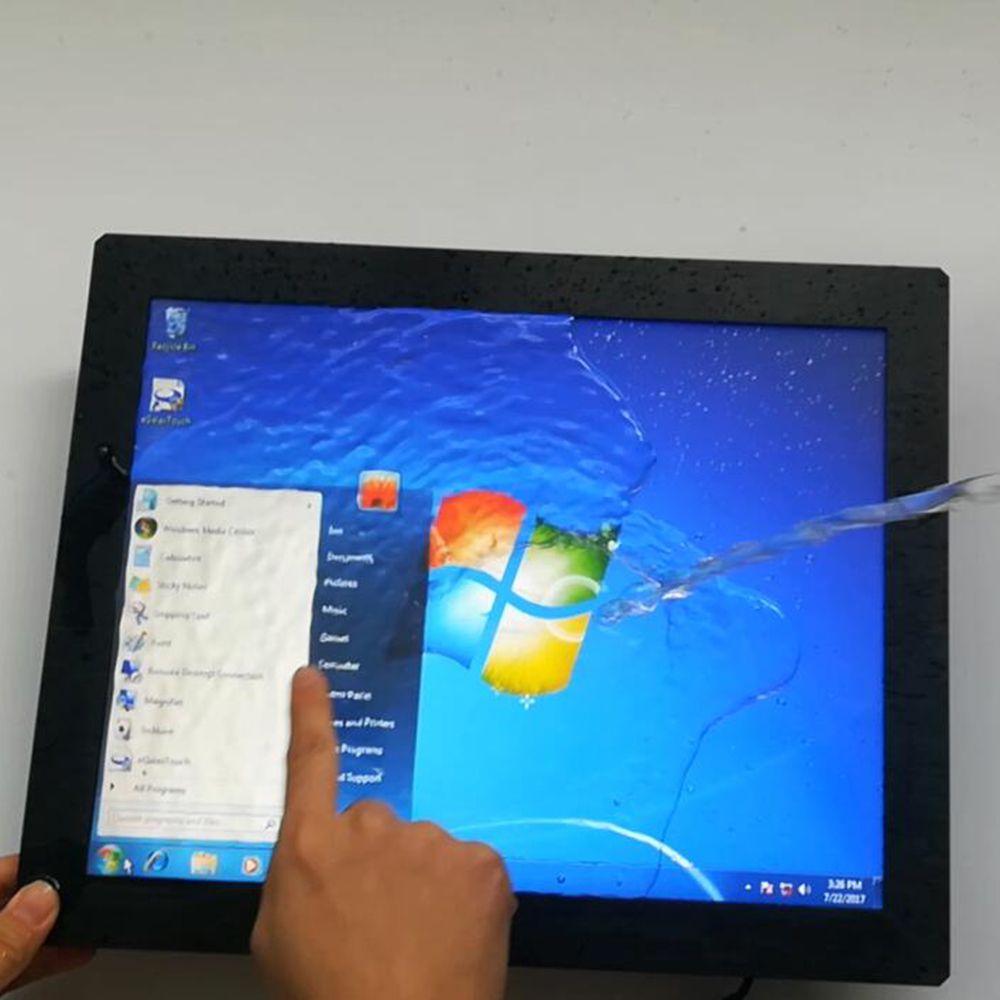

Touchscreen technology has become an integral part of the industrial sector, along with the demand for durable touchscreen equipment installations. Industrial touchscreen monitors are designed to withstand harsh environments and provide reliable performance under challenging conditions. These industrial touch screen monitors are designed with rugged components that can withstand extreme temperatures, high humidity, dust particles, shock or vibration. Industrial touch screen monitors with resistive touch technology are critical for a variety of industries that require reliable display solutions.

Industrial grade monitors are a must-have for a variety of industries. They offer high resolution and use different types of touch screen technology to meet specific needs. These touchscreen monitors feature customised mounting options, multiple connectivity options including USB ports, and integrated power supplies. They also feature a built-in security system that prevents tampering or unauthorised access, making them ideal for touchscreen technology. With these advanced features, industrial-grade monitors ensure long-term reliability even under harsh conditions.

Finally, when choosing an industrial monitor for your application needs, it's important to consider how well the device integrates with your existing systems. This includes aspects such as compatibility with the software platform used by the organisation and the network connectivity features required for remote access control, if required. By taking all factors into consideration, you're sure to get high-resolution displays with capacitive touch capabilities, providing a quality solution that meets current and future needs. In addition, these monitors ensure long-term durability regardless of environmental factors or user activity levels.

Touch Technology

Touch technology is rapidly evolving in a variety of industries, including industrial and commercial. Industrial touchscreen monitors are designed to be durable, reliable and user-friendly, making them the right choice for maintenance in these industries. They offer advanced features such as multi-touch functionality and high-resolution displays. Rugged touchscreens are designed to withstand harsh environments, including exposure to dust, dirt, humidity, vibration or extreme temperatures. Customised touchscreens allow the interface of an application to be tailored to meet specific business needs. With touchscreen connectivity, users can easily access information from multiple devices without having to manually switch between them.

Benefits of using touch technology in industrial displays include increased efficiency and accuracy. Users can work more efficiently with faster inputs compared to traditional keyboards. The flexibility of how data is presented on industrial displays allows for better customisation. In addition, the ergonomics of touch technology enhance the user experience by eliminating the need for a mouse or trackpad. Modern touchscreen technology also supports gesture control, providing professionals with more intuitive interface control. This makes it easier for businesses in all industries to design customised solutions that fit their needs.

Finally, one of the major benefits of applying touch technology to professional workflows is its scalability: most of the hardware components used in these systems (e.g., industrial monitors) can be easily scaled up or down depending on the size requirements needed for the task at hand (which means that businesses) Regardless of the type of project they're working on, people in all industries won't have too much trouble finding the right solution! Combine all of these benefits together, and it's easy to see why so many companies are turning to touchscreen solutions when looking for ways to increase productivity and enhance the customer experience - making them a valuable feature for industries now and in the future!

Industrial Touchscreen Monitors Sizes and Resolutions

Industrial touchscreen monitors are designed to provide the highest level of performance in challenging environments across industries. They come in a variety of sizes and resolutions to fit any business application. Depending on your needs, you can choose industrial monitors that are dust and water resistant with single or multi-touch capabilities. Size and resolution also determine the type of connectivity options available, such as USB, Ethernet or wireless interfaces. With customised touchscreens tailored to specific applications, users get reliable, accurate data input even under extreme conditions.

Touchscreen technology for harsh environments

Recent advances in touchscreen technology have enabled industrial displays to operate reliably in harsh business conditions, where traditional computing devices can fail due to vibration or moisture. This makes them an ideal solution for harsh commercial environments such as factories, warehouses and outdoor areas with frequent temperature fluctuations or high levels of dust particles. State-of-the-art features such as projected capacitance (PCAP) technology allow for precise operation even when wearing gloves, while the IP rating ensures that liquids are prevented from entering the device's enclosure structure, making it highly resistant to corrosion.

Customised touchscreen connectivity solutions

For mission-critical business operations where downtime is intolerable, customised touchscreen displays offer powerful connectivity solutions designed specifically to meet customer requirements. With direct control over design elements such as display size, brightness, and anti-glare coatings, business customers can rest assured that their systems will always operate optimally, no matter what environment they are used in. In addition, advanced technologies such as embedded wireless Communication modules allow business operators to seamlessly integrate into existing networks so they do not need to install additional hardware components on site, saving time and money on installation costs.

Connectivity

Connectivity is critical to the proper functioning of touchscreen displays in the business sector. Whether it's an industrial touchscreen, a ruggedised touchscreen or a custom touchscreen, reliable connectivity is essential. When businesses are considering purchasing one of these types of products, it is important to consider the connectivity options available.

The most common types of connections found in industrial touchscreen monitors are Ethernet cables or Wi-Fi networks. These connections offer high-speed data transfer speeds, which are useful for applications that need to transfer large amounts of data quickly and reliably. In addition, using an Ethernet or Wi-Fi network allows multiple users on different devices in the same building or area to access the same information without the need for additional hardware such as routers or switches.

For those who require a more specialised solution, various other forms of connectivity are also available, including USB ports and wireless standards such as Bluetooth® and Zigbee® technologies, which offer greater flexibility in terms of the distance covered by the signal range of a single device, while allowing secure communications Transmission between two points over short distances with minimal interference from external sources such as radio waves or electromagnetic fields. Ultimately, before investing in any type of touchscreen solution, careful consideration should be given to the form of connectivity that best meets your needs so that you can get the most out of your investment now and in the future.

Industrial Touch Screen Monitor Customisation

Industrial touchscreen monitors are becoming increasingly popular in the workplace due to their ability to be customised for a variety of applications. With touchscreen technology, users can easily access information and control various systems without the need for physical buttons or switches. This makes them ideal for industrial environments where safety is paramount. In addition, these monitors offer greater flexibility as they can be customised to meet the specific needs of the environment. For example, ruggedised versions are available, enabling them to withstand harsh conditions while still providing reliable performance. In addition, customised solutions such as multi-touch functionality and enhanced connectivity options enable businesses to get exactly what they need from their monitor setup.

Benefits of Customised Touchscreen Monitors

When it comes to customising industrial touchscreen monitors, there are a number of benefits that come with this option. Firstly, you gain greater accuracy when using the equipment as all input commands will be specifically designed for your exact requirements; this means fewer errors overall and more efficient operations. In addition, customisation gives you greater control over how data is displayed on the screen, meaning that operators can quickly find what they're looking for without any hassle or confusion - this is particularly important in time-sensitive industries such as manufacturing and logistics operations, where every second counts! Finally, by utilising advanced features such as multi-touch functionality or improved connectivity options (e.g. USB), companies can achieve higher levels of productivity than ever before due to faster response times between devices connected via a single system interface.

Touchscreen Connectivity: The Future of Industrial Environments

As technology continues to advance across today's industry sectors, one area that has seen significant growth recently is touchscreen monitor connectivity. This advancement allows users unprecedented control over their workflow through simple access points located directly on the hardware device itself, rather than relying solely on traditional keyboard/mouse combinations. Not only does this mean that less training time is required, but it also helps to significantly reduce user fatigue and ultimately increase efficiency throughout the organisation - something that cannot be ignored given the competitive nature of most modern businesses today! As well as offering superior ergonomics when compared to other methods, touchscreen monitor connectivity also offers additional security measures not available elsewhere, ensuring that data remains secure at all times, regardless of who may be attempting to access it maliciously.

Frequently Asked Questions

What is the importance of industrial touchscreen monitors?

Industrial touchscreen monitors are vital for professionals as they provide an enhanced user experience with greater accuracy and reliability, leading to more efficient data entry and performance optimisation. In addition, they are designed to withstand tough industrial working conditions, so users can rely on them even in the harshest environments.

How does custom touchscreen technology work?

Custom touchscreen technology works by using capacitive sensing to detect and measure changes in electrical currents that occur when a user interacts with a surface. This data is then interpreted and converted into actions such as scrolling, selecting or activating functions on the device.

What are the benefits of ruggedised touch screens?

Ruggedised touchscreens offer enhanced durability and improved usability in a variety of challenging environments. This includes increased resistance to environmental contaminants, vibration, shock, dust and water ingress, as well as improved readability in direct sunlight. In addition, they offer greater accuracy than traditional buttons or keypads for precise data entry functions.

How do touchscreens connect to other devices?

Touchscreens can be connected to other devices through a variety of wired or wireless connectivity solutions, such as HDMI, USB-C, Wi-Fi, Bluetooth, and more.

Conclusion

Some of the key factors to consider when choosing the right industrial touchscreen monitor include the touchscreen technology, the durability of the touchscreen, and custom or dedicated connectivity options. It is vital to choose industrial-grade touchscreen monitors with multi-touch capabilities that can withstand harsh environments. Likewise, it is important to ensure compatibility between existing computer systems and laptops used by employees. Finally, a reliable form of connectivity must be established to allow for efficient data transfer between the user's operating system and the applications contained within. These criteria will help you make an informed decision when selecting the right industrial quality touch screen monitor that can cost-effectively meet the needs of the user while providing excellent performance in unfavourable conditions.

Comments

0